Hauv cov khoom siv hluav taws xob niaj hnub no tau siv dav hauv cov keeb kwm digital, keeb kwm yav dhau los, sab hauv tsev vim nws lub neej siab, lub neej ntev thiab lwm yam zoo. Hauv kev tsim khoom lag luam ntawm LED zaub, encapsulation technology yog qhov txuas tseem ceeb. Ntawm lawv, SMD encapsulation technology thiab cob encapsulation technology yog ob lub ntsiab txuj ci siab. Yog li, dab tsi yog qhov txawv ntawm lawv? Kab lus no yuav muab rau koj muaj kev soj ntsuam kom tob rau koj.

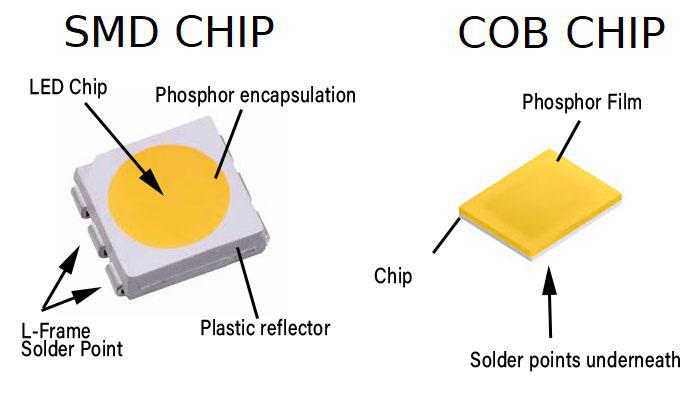

1.What yog smd ntim tshuab, smd ntim cov ntsiab lus

SMD pob, tag nrho lub npe nto sib cav sib ceg (khoom siv hluav taws xob ncaj qha welded rau cov tshuab luam ntawv (PCB) ntim sab saum toj. Cov thev naus laus zis los ntawm precision tso tshuab, lub encapsulated ruckulation siv nti (feem ntau muaj cov teeb pom kev zoo thiab lwm txoj hauv kev kom paub qhov hluav taws xob txuas.smd ntim khoom Tshuab ua rau cov hluav taws xob hluav taws xob me dua, sib dua hauv qhov hnyav, thiab ua kom haum rau kev cog lus hluav taws xob ntau dua thiab cov khoom hluav taws xob.

2.Qhov zoo thiab qhov tsis zoo ntawm SMD TV TV thev naus laus zis

2.1 smd ntim tshuab zoo

(1)Loj me me, lub teeb hnyav:SMD cov khoom ntim yog qhov me me, kom sib xyaw ua ke, kom nruj kev ua kom muaj zog, ua rau cov miniaturized thiab teeb hluav taws xob hauv hluav taws xob.

(2)Cov yam ntxwv zoo-zaus:Cov ntawv nrov luv luv thiab luv luv txuas kev pab txo qhov tsis pom kev thiab kev tawm tsam, txhim kho kev ua tau zoo.

(3)Yooj yim rau kev hloov kho tau:Haum rau kev tso cav tshuab ntau lawm, txhim kho ntau dua qub thiab zoo ruaj khov.

(4)Zoo thermal Performance:Sib cuag ncaj qha rau PCB saum npoo av, ua rau kub ua rau kub dissipation.

2.2 smd ntim tshuab kev cuam tshuam thev naus laus zis tsis zoo

(1)Kev Tu Kom Zoo Li Qub: Txawm hais tias txoj kev mounting sib txawv ua rau nws kho tau yooj yim dua thiab hloov chaw sib xyaw ua ke, hloov ntawm cov khoom siv ntawm tus kheej yuav yog cumbersome ntau dua.

(2)Tsawg cua sov dissipation cheeb tsam:Feem ntau los ntawm cov ntaub qhwv thiab gel tshav kub disspipation, ntev lub sij hawm thauj khoom ua haujlwm yuav ua rau kub, cuam tshuam rau lub neej pabcuam.

3.Qhov yog COB ntim tshuab, COB COB LOJ

COB Pob, lub npe hu ua Chip ntawm Board (nti ntawm Board pob), yog liab qab ntawm kev siv thev naus laus zis ntim rau PCB. Cov txheej txheem tshwj xeeb yog cov nqaij tawg paj (nti lub cev thiab kuv / o terminals sib khi mus rau PCB, thiab tom qab ntawd los ntawm txhuas lossis kub xaim) hauv ultrasonic, hauv qab qhov kev txiav txim Ntawm tshav kub kub, lub nti ntawm kuv / o terminals thiab pcb pads tau txuas nrog, thiab thaum kawg kaw nrog resin nplaum tiv thaiv. Qhov encapsulation tshem tawm cov lig led teeb tsa teeb encapsulation cov kauj ruam, ua pob ntau compact.

4.Qhov zoo thiab qhov tsis zoo ntawm COB ntim tshuab ntim tshuab

4.1 COB Ntim Tshuab Ntim Zoo

(1) Cov pob me me, qhov loj me me:Tshem tawm hauv qab pins, kom ua tiav ib pob me me.

(2) kev ua tau zoo dua:Cov xaim xaim kub txuas cov nti thiab cov kev sib txuas lus Circuit Court, qhov teeb liab kev sib kis deb yog luv luv, txo cov crostsalk thiab kev ua tsis tau zoo thiab lwm yam teeb meem los txhim kho kev ua tau zoo.

(3) cua sov tsis zoo:Lub nti yog ncaj qha welded rau PCB, thiab kub tau dissipated los ntawm tag nrho cov PCB board, thiab tshav kub yooj yim dissipated.

(4) Kev tiv thaiv zoo:Tag nrho cov kev tsim qauv, muaj dej noo, noo noo-pov thawj, pov thawj, anti-promic thiab lwm yam kev tiv thaiv.

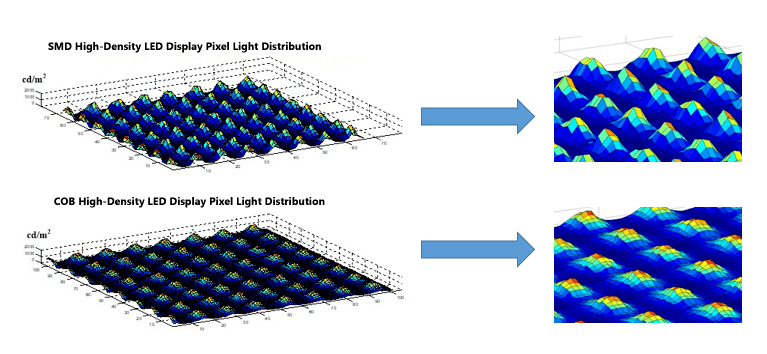

(5) Kev pom kev zoo:Raws li lub teeb ci saum npoo av, cov xim ua tau zoo dua, kev nthuav dav zoo dua, tsim nyog rau lub sijhawm ntev saib.

4.2 COB NTEV siv thev naus laus zis tsis zoo

(1) kev txij nkawm nyuaj:Nti thiab PCB coj mus thaiv ncaj ncees, tsis tuaj yeem cuam tshuam sib cais lossis hloov lub nti, cov nqi txij nkawm muaj siab.

(2) nruj me ntsis uas yuav tsum muaj:Cov txheej txheem ntim ntim ntawm ib puag ncig yeej yog qhov siab heev, tsis tso plua plav, hluav taws xob zoo li qub thiab lwm yam kev paug.

5. Qhov sib txawv ntawm SMD lub tshuab ntim tshuab thiab COB ntim tshuab

SMD encapsulation Technetulationing Technumelfulation Technology hauv tshav pob ntawm cov qauv encapsulation, loj thiab qhov sib txawv, yooj yim ntawm kev saib xyuas thiab daim ntawv qhia txog kev lom zem. Cov hauv qab no yog cov ncauj lus piav qhia ntxaws ntxaws thiab tsom xam:

5.1 Cov Qauv Ntim

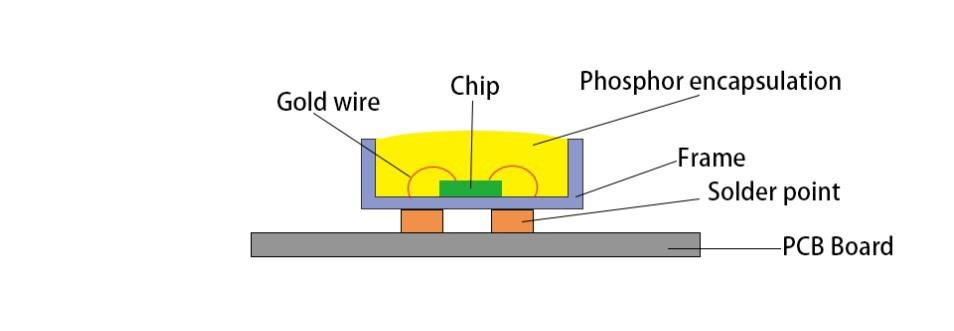

⑴SMD Ntim Technology: Tag nrho lub npe yog cov cuab yeej siv nto sib tw, uas yog lub tshuab ntim khoom uas tau siv nti rau ntawm cov chaw tsim hluav taws xob (PCB) los ntawm cov duab kos npe. Txoj kev no yuav tsum tau nti cov hnoos qeev kom ntim ua ntej los tsim cov khoom ywj siab thiab tom qab ntawd mounted ntawm PCB.

⑵COB TV Technology: Tag nrho lub npe yog nti nyob rau hauv board, uas yog lub tshuab ntim khoom siv ncaj qha uas ncaj qha rau tus pcb liab qab rau ntawm pcb. Nws tshem tawm cov kauj ruam ntim cov khoom ntim ntawm cov lig kev cai LED teeb rau tus pcb nrog kev coj ua lossis thermal cov kua nplaum, thiab paub cov khoom siv hluav taws xob sib txuas los ntawm cov hlau hlau.

5.2 Qhov loj thiab qhov hnyav

⑴SMD Ntim: Txawm tias cov khoom siv yog qhov me me, lawv qhov loj me thiab qhov hnyav yog tseem muaj kev txwv vim ntim cov qauv thiab cov ntaub qhwv.

⑵COB Pob: Vim yog cov tsis muaj qab pins thiab pob plhaub, cob pob ua tiav ntau qhov kev sib xyaw ua ke, ua kom lub pob me dua thiab sib dua.

5.3 Kev ua cua sov sov dissipation

⑴SMD Ntim: Feem ntau tsis cuam tshuam thaum tshav kub los ntawm cov ntaub qhwv thiab colloids, thiab thaj sov dissipation cheeb tsam yog qhov tsawg. Nyob rau hauv lub siab ci ntsa iab thiab siab thauj cov xwm txheej, tshav kub tuaj yeem muaj ntau nyob hauv thaj chaw chip, cuam tshuam rau lub neej thiab kev ruaj khov ntawm cov zaub.

⑵COB Pob: Cov nti yog ncaj qha welded ntawm PCB thiab cua sov tuaj yeem tsis txaus ntseeg los ntawm tag nrho cov pcb board. Qhov kev tsim qauv no tseem txhim kho cov cua sov dissipation kev ua tau zoo ntawm cov zaub thiab txo qhov tsis ua haujlwm ntawm kev kub ntxhov.

5.4 Kev Yooj Yim ntawm Kev Kho

Siv Ntim: Txij li cov khoom siv tau nce nws tus kheej ntawm PCB, nws yog qhov yooj yim los hloov ib qho tivthaiv thaum lub sijhawm tu. Qhov no yog qhov tseem ceeb los txo cov nqi txij nkawm thiab lub sijhawm tu luv.

Kev ntim ntim ntim: txij li lub nti thiab PCB yog ncaj qha welded rau tag nrho, nws yog tsis yooj yim sua disassemble lossis hloov lub nti sib cais. Thaum ib qho txhaum tshwm sim, feem ntau yog tsim nyog los hloov tag nrho cov PCB pawg thawj coj lossis xa rov qab rau lub Hoobkas rau kev kho, uas nce tus nqi thiab kev kho nyuaj.

5.5 Daim Ntawv Teev Npe

⑴SMD Ntim: Vim nws cov nqi loj hlob zoo thiab muaj ntau tus nqi tsim khoom, tshwj xeeb yog kev ua haujlwm yooj yim, xws li cov phab ntsa billboards sab nraum zoov thiab sab nraum zoov TV phab ntsa.

Kev tiv thaiv ntim khoom: Vim nws cov kev ua tau zoo thiab kev tiv thaiv sab hauv tsev thiab lwm yam kev xav tau thiab cov chaw muaj kev sib txuam. Piv txwv li, hauv cov chaw ua haujlwm tom ntej, studios, cov chaw xa khoom loj thiab lwm qhov chaw uas ua haujlwm ntim tau ntev, CAR NTIM cov khoom siv tau ntev dua thiab muaj kev pom kev zoo dua.

Tag

SMD ntim thev naus laus zis thiab cob ntim tshuab txhua tus muaj lawv tus kheej tshwj xeeb cov txiaj ntsig thiab cov xwm txheej ntawm daim ntawv teev cov teeb pom kev. Cov neeg siv yuav tsum hnyav thiab xaiv raws li cov kev xav tau tiag tiag thaum xaiv.

SMD lub tshuab siv thev naus laus dua thiab COB ntim tshuab muaj lawv tus kheej. SMD Cov thev naus laus zis siv tau dav hauv kev ua lag luam vim nws lub siab loj hlob thiab cov nqi tsim khoom ntau, tshwj xeeb yog nyob hauv cov dej num uas raug nqi ntau yam yooj yim. COB Ntim thev naus laus zis, ntawm qhov tod tes, muaj cov kev sib tw hauv tsev, cov chaw saib xyuas pej xeem, zoo tshaj cua sov dissipation thiab kev tiv thaiv cua sov thiab muaj zog tiv thaiv.

Lub Sijhawm Post: Sep-20-2024